Our company is CO₂ certified

10/21/2022 |

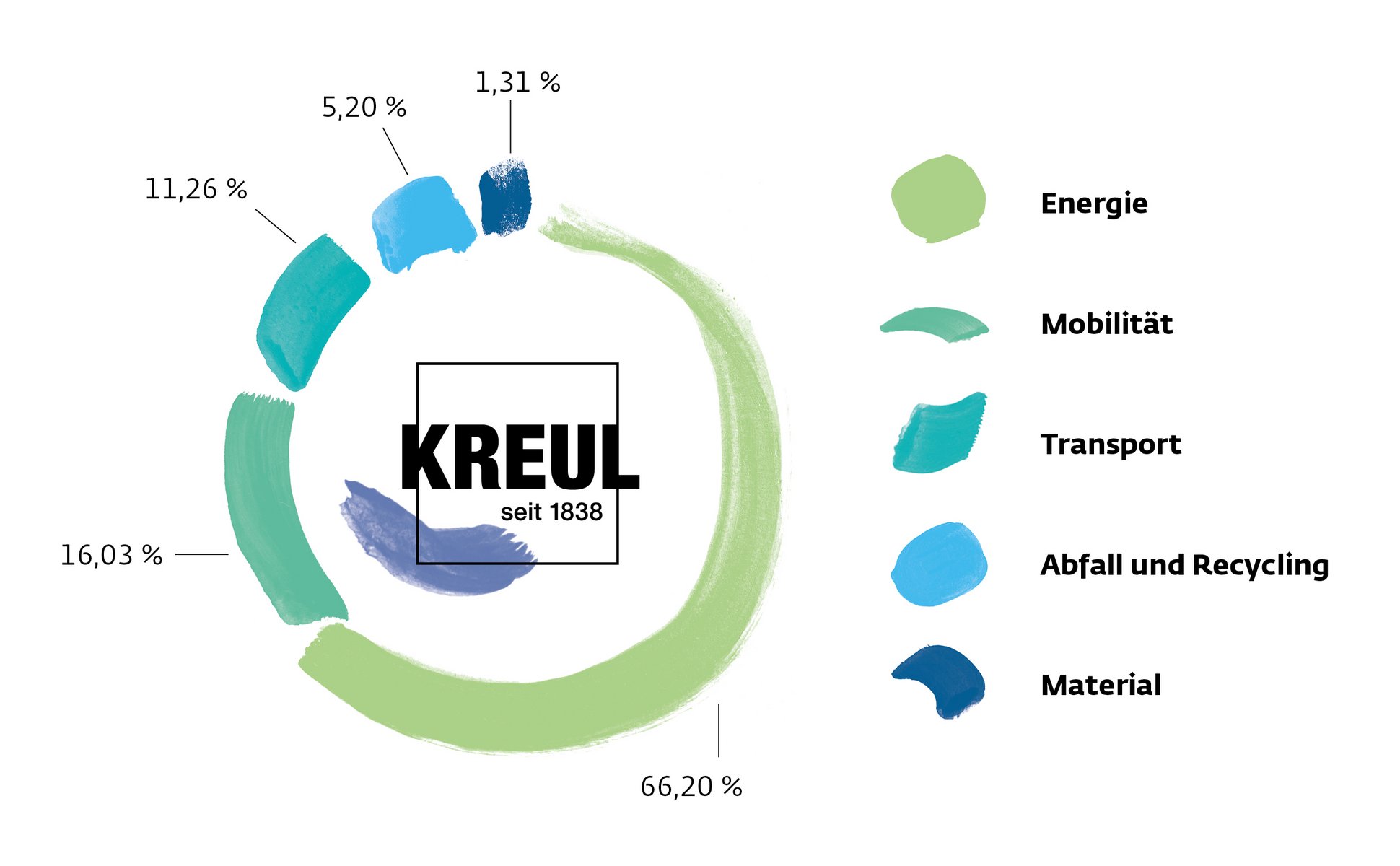

This is how the Corporate Carbon Footprint for KREUL is calculated

In the CO₂ footprint of a company, the Corporate Carbon Footprint (CCF), all the relevant CO₂-emissions within a year are calculated. The methodical approach is based on internationally recognized standards (ISO 14064, GHG Protocol, CDP, GRI). Together with the not-for-profit foundation myclimate, we drew up a corporate CO₂ footprint for our operations in 2021. From now on, our CO₂ footprint will be recalculated every year. We have calculated the greenhouse gases emitted during paint and product manufacture at our sole corporate base in Hallerndorf. A total of 920.44 t CO₂ emissions currently has to be offset.

What key figures are taken into account in the calculation of our footprint?

• Emissions from the electricity we buy in to meet the needs of our production and administration

• Indirect emissions, e.g. from business trips, employees' travel to work, IT and company waste

We don't take into account:

• Upstream production of raw materials and other materials

• Upstream and downstream logistics

Targeted reduction of CO₂ in our corporate processes

We not only derive the total quantity of emissions from the CO₂ footprint. We can clearly identify the company processes in which the largest quantities of CO₂ are produced. So we can target and reduce CO₂ emissions in these processes:

- From 2020 to 2021, with flexible working times and home office opportunities, we reduced the fuel consumption of company-owned vehicles by 30 %.

- Since 2022, we have been supplied with 100 % green power.

- We use smart planning to schedule the production of large batches and in this way we reduce the energy we need to make our paints.

- Thanks to more efficient utilization of space, we are lowering our heat and power requirement.

- With, for instance, an electric vehicle charging station or a cycle leasing scheme: We give our employees incentives to save CO₂ on their way to work.

- No costly mixing processes, smart selection of raw materials, water-based formulatons and minimized intermediate stages: already during the development of our paints and products, we take care to ensure the responsible use of resources. This means that both our production processes and our products are becoming more efficient and environmentally friendly.

Compensation through the support of a conservation project in Tanzania

There are lots of options to offset CO₂ emissions. We have chosen a project in which we are working to conserve Tanzanian forests for indigenous people, wildlife and the climate (tracking ID: myclimate.de/01-22-895656). Sustainability never stops and we have a long road ahead. But with the CO₂ footprint and the measures we have derived from this, we have made a big step into a more sustainable future for the manufacture of our paints.